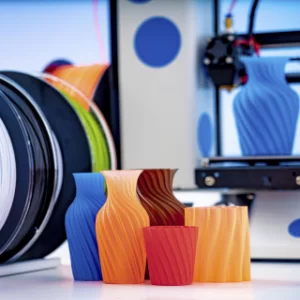

Low-Volume Production

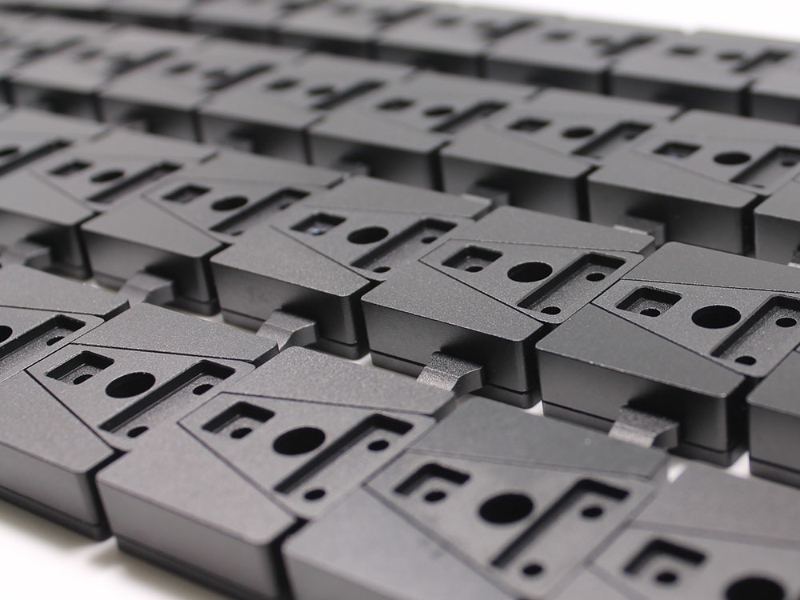

In today's diversified market, in order to meet the needs of market development. With the rapid progress of technology and the increasing competition, a large number of new products are developed, and small batch production has become the key for enterprises to win competitive advantage. Yunsheng Technology can quickly complete CNC machining parts, precision turning parts, die casting parts, injection parts, investment casting parts, stamping parts and other materials. And can quickly complete production and delivery.

Small batch customization service

if you need custom machined parts with complex geometries, or get end-use products in the shortest possible time.

Shenzhen Yunsheng is good enough to break through al of that and achieve your idea immediately.

From CNC Prototyping to Production

Shenzhen Yunsheng Technology Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Small batch customization service

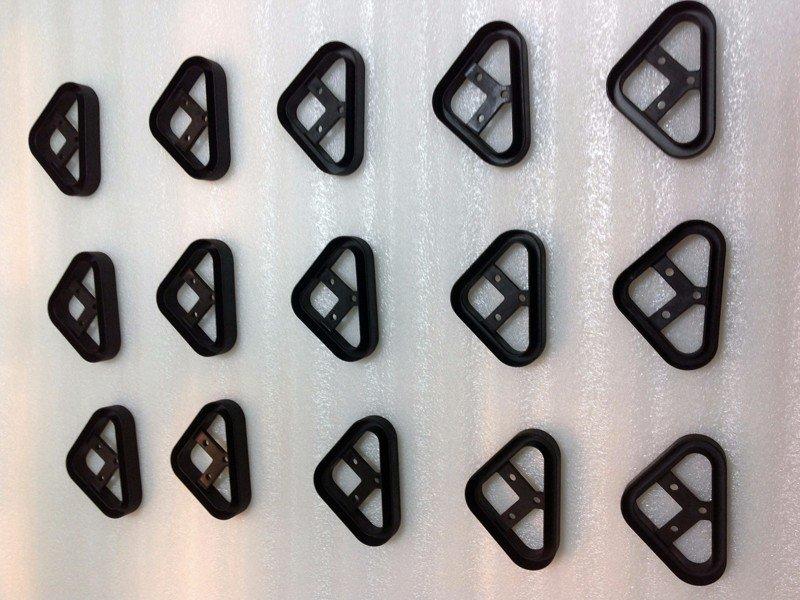

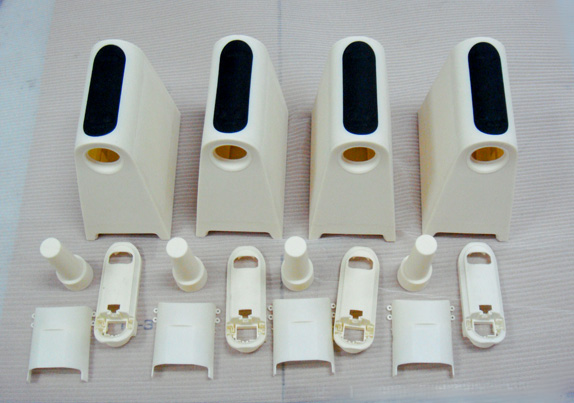

In today’s diversified market, in order to meet the needs of market development. With the rapid progress of technology and the increasing competition, a large number of new products are developed, and small batch production has become the key for enterprises to win competitive advantage. Can quickly complete CNC machining parts, precision turning parts, die casting parts, injection parts, investment casting parts, stamping parts and other materials. And can quickly complete production and delivery.

-

Materials

Materials

Plastic: ABS, PC, POM, PMMA, PC, PP, PETF, bakeries, etc. Metal: Aluminum alloy, stainless steel, titanium, brass, etc. Can be processed according to the material scheme provided by you.

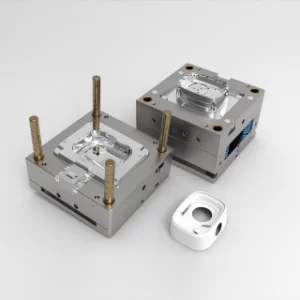

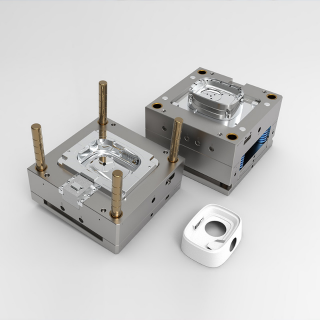

Small Molded Parts within Days

Insightprototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

Small batch customization service

|

Painting | Painting the surface of a part improves its aesthetic appearance and can provide brand recognition to consumers. In addition, painting can have a protective effect on parts. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing |

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. |

Aluminum, Brass, Stainless Steel, Steel |

n/a | Gloss |

Small batch customization service

Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

What Our Customers Say

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Small batch customization service

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

About the CNC Milling Process

With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can be also a cylindrical rodi). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

Frequently Asked Questions

What are the advantages of CNC machining?

What are the different types of machining processes?

What industries use CNC machinery?

What are standard machining tolerances?

Latest Blog Posts

Follow Yunsheng to learn more CNC industry information!