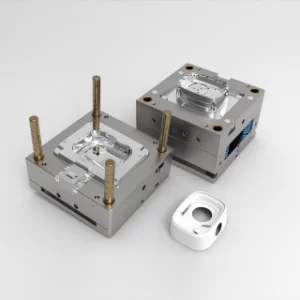

Rapid CNC Machining Service

If you need custom machined parts with complex geometry, or an end-use product in the shortest possible time, we have enough to break through all of that and realize your idea instantly. We operate more than 150 3, 4 and 5-axis CNC machines and offer 100+ different types of materials and finishes, guaranteeing quick turnaround and quality of disposable prototypes and production parts.

CNC Milling:

Engineered components featuring flat surfaces are crafted through CNC milling. This is done by utilizing a cutting tool, or multi-point milling cutters, to remove portions of the workpiece material to meet customized designs.

Our CNC milling services employ the latest 3 and 5-axis technology to deliver parts with incredibly tight accuracy measurements – as small as a mere 0.02mm (±0.0008 in.)! Whether you need parts machined with precision or complex geometries, our CNC milling capabilities can get the job done in an efficient and cost-effective manner.

CNC Turning:

CNC turning shears materials from the ouside of a rod at incredible speeds using a spinning tool. At RapidDirect, we apply 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision that consistantly meet customers’ expectations.

CNC process:

- Import the prototype design document into the 3D processing software, and the programmer can write the processing program at the lowest cost and fastest processing speed.

- Order raw materials and set up processing tools. These will be clamped on the CNC machining platform.

- CNC cuts and removes unnecessary materials according to a predetermined processing program.

- The machinist finally completes the required prototype parts by changing different types of tools and adjusting the clamping of the processed parts until all parts that do not require materials are cut.

- Take off the prototype, clean the burrs, and sandblast, polish, paint, etc.

- Prototype assembly and size inspection.

Advantages of CNC machining

CNC machining is very suitable for the application of the prototype industry and the prototype production in your early product development. This is also the most mainstream production process. The following are the advantages and disadvantages of CNC prototype processing:

- High precision

- You can choose a variety of materials to process various plastics, metals, woods, foams, etc.

- Fast processing speed, can quickly realize the conversion from 3D image files to physical objects.

- The prototype produced can have the same performance as the product produced by the mold.

- Low production cost and simple fixing.

- Quick response and short cycle.

- Our company has 11 years of experience in CNC prototype processing, and has accumulated rich experience in various fields including automobiles, household appliances, medical care, intelligence, etc., and can produce prototypes quickly, efficiently, and at low cost.